TOC·TN·TP Load Reducer & Odor Eliminator

ONPLROE

- Purpose = TOC·TN·TP Load Reducer & Odor Eliminator (ONPLROE)

- Role = Pretreatment Device in STP & WWTP (PDiSW)

- Method = Rotating Activated Bacillus Contactor (RABC)

- Function = Endospore-Forming Bacteria Bioreactor (EFBB)

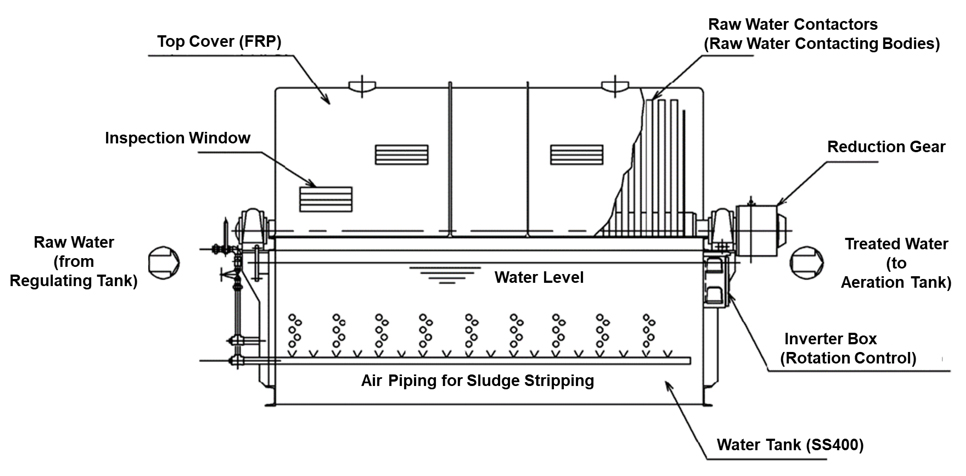

The ONPLROE is used to remove odors and to reduce the load of organic matter, nitrogen, and phosphorus with microorganisms adhered to several rotating loofah-shaped contactors of 50 mm in thickness and 1,000 mm or 2,000 mm in diameter, which are brought into contact with sewage and wastewater. By installing in the front stage of various reaction tanks such as anaerobic tanks, anoxic tanks, and aeration tanks, the load of organic matter, nitrogen, and phosphorus is greatly reduced, so the reaction tanks in the latter stages become smaller. The amount of air required for the aeration tank is also reduced. Furthermore, the amount of air required for the aeration tank is reduced, resulting in a significant reduction in power consumption. Excess sludge is also significantly reduced compared to conventional methods (depending on the concentration of solids in the influent) because of the biological membrane method.

The contacting bodies of the device are made of PVDF, which is the same material as Saran Wrap, curled and processed into a scrubbing brush shape, and the product name is SaranLock (patent obtained for processing). 6 fan-shaped pieces of material, each 50 mm thick, are combined to form a 1,000 mm or 2,000 mm disk. The ONPLROE is made by combining 12 to 30 disks of the material into a unit.

Internal Contactors (30 Disks)

Production Completed

The water level of the unit is designed so that the disks are immersed about 40%, and while raw water flows in from the side and treated water overflows out from the diagonal side, microorganisms attached to the contacting bodies decompose and remove about 60% to 70% of the organic matter (BOD, etc.) and intake and remove 40% to 50% of nitrogen in the raw water. Oxygen supply to microorganisms is usually forced by blower airflow, but the ONPLROE rotates the contactors at low speed to bring in oxygen from the atmosphere, resulting in highly efficient treatment.

Since microorganisms are constantly multiplying, air is constantly supplied from the PVC piping installed at the bottom of the unit to detach the sludge for preventing excessive adhesion to the contacting bodies and clogging, thereby keeping the microorganism adhesion constant and the treatment capacity unchanged.

Excessive Adhesion

In Good Condition

No complicated maintenance is required. The grease in the bearings (pillow blocks) needs to be replenished once a month, and the status of sludge adhesion needs to be checked visually through the inspection window every day. The control of sludge amount adhered is done only by adjusting the air valve for stripping, which does not need to be done daily.

The service life is approximately 10 years. If the internal contactors are partially damaged, they can be replaced. There are many cases where the ONPLROE has been used for more than 10 years before a hole appears in the tank. The main shaft has been improved and strengthened over the past few decades, so there is no need to worry about it breaking.

Contactors Being Replaced

After Replacing Contactors

| Model | Contactor Dimensions(mm) | No.of Disk | Surface Area | Contact Tank Volume | Self-Weight | Opera-ting Weight | External Dimensions(LxWxH) (mm) | Agitation Air Volume | Power |

|---|---|---|---|---|---|---|---|---|---|

| ONPLROE-1012 | Φ1000×50t | 12 | 75m² | 1.1m³ | 0.6 | 2.5 | 2051x 1330x 1515 | 0.4m³/min | 200V×0.4kw |

| ONPLROE-1024 | Φ1000×50t | 24 | 150m² | 1.9m³ | 1.1t | 3.8t | 3191x 1330x 1515 | 0.6m³/min | 200V×0.4kw |

| ONPLROE-2012 | Φ2000×50t | 12 | 300m² | 3.5m³ | 2.5t | 7.2t | 2372x 2400x 2500 | 0.7m³/min | 200V×0.75kw |

| ONPLROE-2024 | Φ2000×50t | 24 | 600m² | 6.4m³ | 3.5t | 13.1t | 3628x 2400x 2500 | 0.8m³/min | 200V×1.5kw |

| ONPLROE-2030 | Φ2000×50t | 30 | 750m² | 7.8m³ | 3.7t | 15.3t | 4228x 2400x 2500 | 1.0m³/min | 200V×2.2kw |

| Model | Inflow BOD load | Design Removal Ratio | ONPLROE Installation Space | Converted to Aeration Tank | Aeration Tank Installation Space | Initial Cost |

|---|---|---|---|---|---|---|

| ONPLROE-1012 | 30kg・BOD/d or less | 60% | Approx. 4m² | Approx. 40m³ Equivalent | Approx. 10m² Equivalent | Less than half (including construction cost) |

| ONPLROE-1024 | 60kg・BOD/d or less | 60% | Approx. 5m² | Approx. 80m³ Equivalent | Approx. 20m² Equivalent | Less than half (including construction cost) |

| ONPLROE-2012 | 120kg・BOD/d or less | 60% | Approx. 7m² | Approx. 160m³ | Approx. 40m² | Less than half (including construction cost) |

| ONPLROE-2024 | 240kg・BOD/d or less | 60% | Approx. 9m² | Approx. 320m³ | Approx. 80m² | Less than half (including construction cost) |

| ONPLROE-2030 | 300kg・BOD/d or less | 60% | Approx. 11m² | Approx. 400m³ | Approx. 100m² | Less than half (including construction cost) |

The ONPLROE is a biological membrane system, and a wide variety of microorganisms live in the contacting bodies. Compared to floating aeration tanks, there are dozens of times more types of microorganisms, which promotes microbial predation and reduces excess sludge. The same effect can be expected from other biological membrane systems such as sprinkler filter beds, carrier fluidized beds, and honeycomb tubes. There are other methods such as solubilizing excess sludge with caustic soda or ozone and feeding it to microorganisms, but there are many problems such as the load on the aeration tank and the increase in COD concentration in the treated water, which can reduce the volume but not eliminate it. In cooperation with other companies, we are working to make effective use of excess sludge by returning it to farmland.

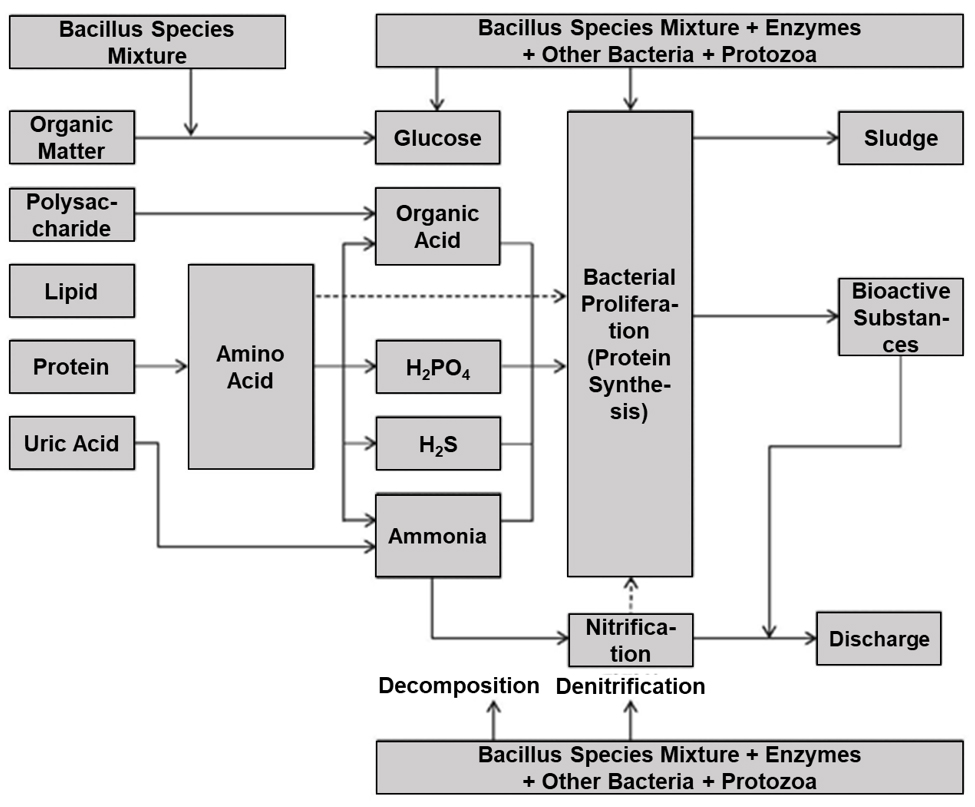

The main treatment mechanism for pollutants is not the conventional biological treatment process, such as oxidation, but the direct ingestion of organic matter, nitrogen, and phosphorus by Bacillus species mixture.

Treatment of Organic Matter

The ONPLROE adheres Bacillus species mixture to its contacting bodies and rotates them to evenly contact the inflow sewage and wastewater, thereby directly ingesting and removing the organic matter contained therein. Bacillus species mixture produces catalase and superoxide dismutase which are powerful hydrolytic enzymes during the propagation process, and breaks down polysaccharides, proteins, lipids, and other hard-to-degrade substances into a form that is easily ingested by microorganisms, thereby enabling treatment of high concentrations of organic matter and persistent organic matter in sewage and wastewater.

Treatment of Nitrogen

Nitrogen is removed by maintaining DO concentrations below 1.0 mg/ℓ, which means that nitrogen sources are not nitrated, i.e., ammonia, ammonium salts, and amines are directly ingested by the Bacillus species mixture. And, this is differentiated from conventional biological treatment process mechanisms that remove nitrogen by inducing denitrification through nitrification. Bacillus species mixture such as B.licheniformis, B.fastidosus, and B.pasteurii grow by ingesting and degrading urea, purine, and ammonium as a source of nitrogen and energy.

The ONPLROE Systems operating at high bioburden concentrations remove nitrogen from wastewater in quantities that cannot be accounted for by the conventional nitrogen-removal processes found in activated sludge systems, namely the nitrification-denitrification process and biomass assimilation.

Four model mechanisms of microbiological nitrogen conversion have been reported to date :

- Nitrification by aerobic autotrophic bacteria → Denitrification by anaerobic heterotrophic bacteria (conventional method)

- Nitrification by aerobic autotrophic bacteria → Denitrification by anaerobic autotrophic bacteria

- Nitrification by aerobic heterotrophic bacteria → Denitrification by anaerobic heterotrophic bacteria (BOD/N>5)

- Nitrite Oxidation by aerobic autotrophic bacteria → Denitrification by anaerobic ammonia-utilizing bacteria (BOD/N < relatively low)

The nitrogen removal model by the ONPLROE System is a combination of these models mentioned above. The weighting of each model will be dependent on the characteristics of the influent to the wastewater treatment plants. The exterior surface biofilm in the ONPLROE contactors can readily absorb the highly concentrated DO and organics and they are effectively similar to the activated sludge biofilm. In particular, operation with low substrate loading, for example sewage wastewater treatment, are attributable to 1) the mechanism of conventional N-removal while also partly 2) the mechanism of anaerobic respiration in the anoxic zone of the biofilm. In the case where organic concentration greatly exceeds nitrogen, then mechanism 3) would have a greater weighting in terms of N-removal. Mechanism 4), the ANAMMOX model serves as an important N-removal aspect in cases with a low C/N ratio such as leachate in landfill.

| Leachate | BOD5 | TN | NH4-N | NO2-N | NO3-N | Alkalinity |

| Influent | 4,211 | 1,527 | 1,380 | 0.5 | 1.6 | 6,994 |

| Effluent | 32 | 152 | 47 | 4.6 | 88.7 | 1,036 |

| Removal(%) | 99% | 90% | 97% | - | - | 85% |

As in activated sludge systems, a high internal recycle flow ratio would be needed to obtain high nitrogen removal.

Treatment of Phosphorus

Phosphorus is ingested and removed by Bacillus species mixture maintained at high concentrations by keeping DO concentrations of about 0.5 mg/ℓ where microorganisms are most likely to ingest. And, this is differentiated from conventional biological treatment process mechanisms that remove phosphorus via the release in anaerobic state and the overdose in aerobic state. The cell walls of Bacillus mixed bacillus contain large amounts of tycolic acid, and because of the presence of glycerol and ribitol linked by phosphate groups, phosphorus uptake is much higher than in Gram-negative bacteria. At a DO concentration of 0.1 mg/ℓ (ORP around 80mV) poly-P synthesis begins and biological phosphorus uptake becomes maximal at 0.5 mg/ℓ (ORP around 200mV). In this case, since the optimal growth conditions for Bacillus spp. in the ammonium salt state without nitrification are DO from 0.1 mg/ℓ to 1.0 mg/ℓ or less, the maximum phosphorus removal rate can be extracted. Assuming that the cellular constituent of phosphorus is C50H87O23N12P, 0.025 kg of phosphorus is required to synthesize 1 kg of cells, accounting for 50% carbon, 20% oxygen, 14% nitrogen and 3% phosphorus but it accounts for 35% of the total mass of the nucleus and is a component of proteins, RNA, and others. And phosphorus is one of the constituents of ATP, nucleic acids and coenzymes NAD, NADP and flavin. The higher the concentration of bacteria, the higher the phosphorus removal efficiency.